6

6

0

Regulation forbids steam pressing, dry cleaning an starching but allows for "roll pressing" uniforms. What is this? And are there other techniques within regs to enhance the appearance of the uniform?

Posted 5 y ago

Responses: 17

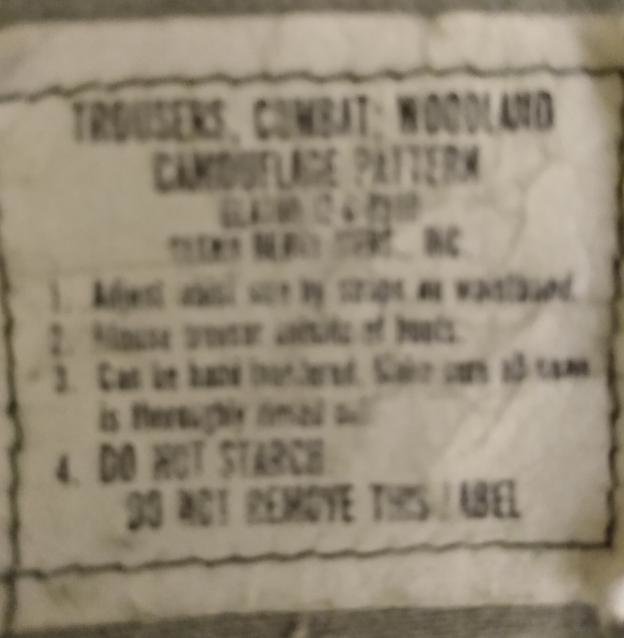

Interesting, most commercial "roll presses" are steam presses. Does the manufacturer care instructions actually have that stated? The roll presses that do not have steam are usually used while the clothing is still damp in a commercial establishment.

(1)

(0)

Turn the legs inside out and iron with sizing. Flip back and put a mild crease on. Watch heat. Any warnings come from mfgr and research folks to preserve materials, and also not add to heat signature. I never gigged anyone for having sharp creases, but it's USMC. The sateen uniform was best for inspections. Spit shined boots, razor creases, polished brass, straight gig line, starched sateen cover, fresh high and tight. Shaven and sober are a given.

(1)

(0)

When the camouflage BDU was introduced, pressing/ironing was forbidden. There was good reason for this, as pressing flattened the surface fibers which acted as a radar scattering factor. Somehow, the "battle dress" became standard garrison attire and the senior leadership realized it looked like c**p. Thus, the "pressed" BDU became the standard. As for roll pressing, your PX or quartermaster laundry knows how to do it.

(0)

(0)

1LT William Clardy

I have to respectfully disagree, 1SG Charles Hunter.

Ironing BDUs was authorized from the first day they were issued to replace the sateen (permanent press) fatigues. And the fibers never had any "radar scattering" properties - the dyes were (expensively) formulated to reduce reflectivity in the near-IR range, a chemical property which was reportedly diminished by ironing at excessively high termperatures.

Ironing BDUs was authorized from the first day they were issued to replace the sateen (permanent press) fatigues. And the fibers never had any "radar scattering" properties - the dyes were (expensively) formulated to reduce reflectivity in the near-IR range, a chemical property which was reportedly diminished by ironing at excessively high termperatures.

(0)

(0)

Suspended Profile

1LT (Join to see) roll-pressing is ironing without creasing. Don’t recall the manual I found it in. Wasn’t AR / DA-PAM 670-1. But the army defines it in its doctrine.

”But don’t take my word for it!”

- LeVar Burton

”But don’t take my word for it!”

- LeVar Burton

Roll Press was invented from the jungle fighters back in the day, since many didn't have access to proper laundery facilities, basically you lay out your uniform tuck the ends to flatten out and remove wrinkles, button up all buttons, fold the sleeves in towards the center , and roll from the bottom right up the front of the uniform . Then it can be stored until use ,either in rucksack, buttsack ,or in barracks drawer. The roll actually presses the uniform, we used to do this with our jungle fatigue uniforms to get the pressed look when they were stored for use.. Hope this helps

(0)

(0)

Read This Next

Army Regulations

Army Regulations OCP

OCP Advice

Advice Professionalism

Professionalism